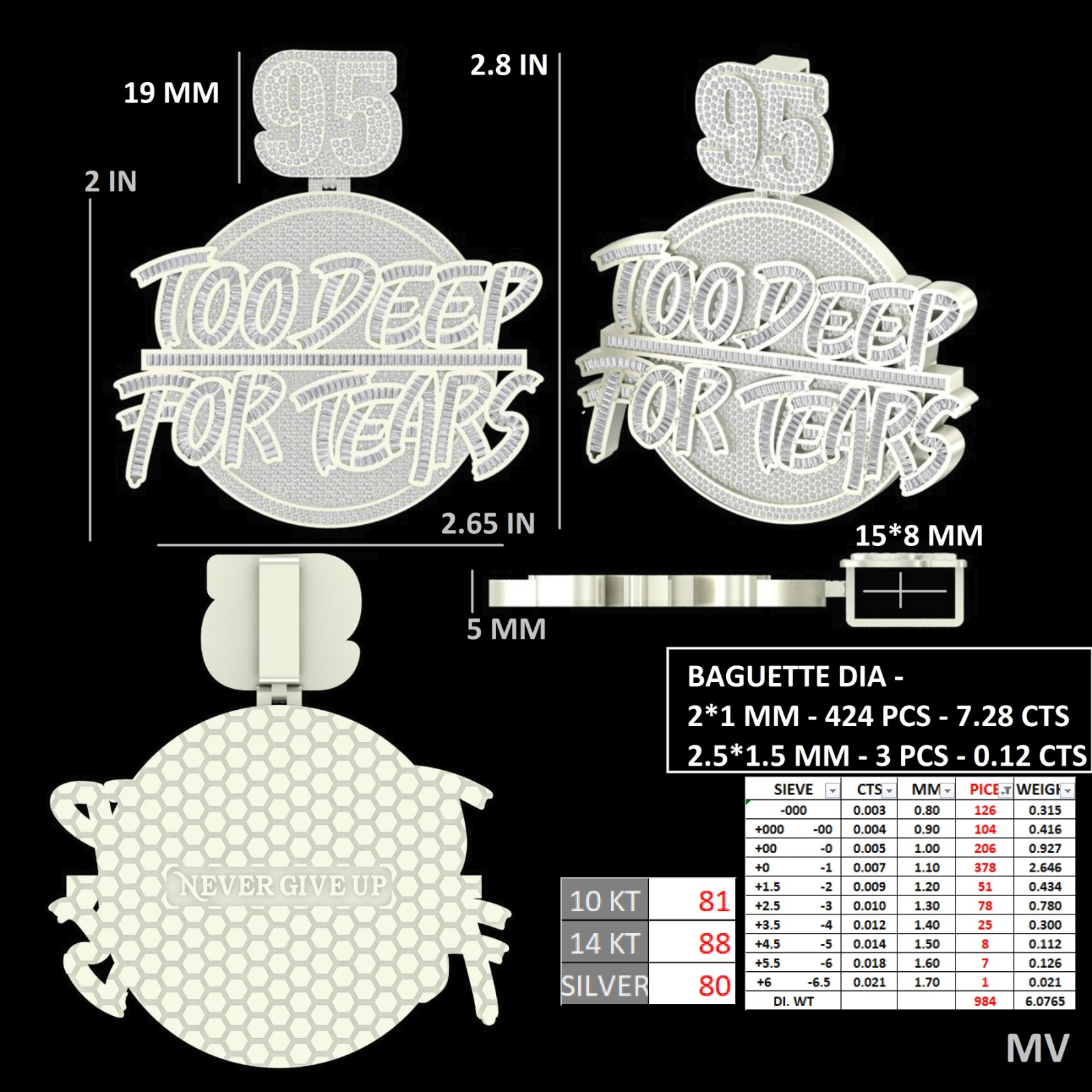

Step 1 : Designing

The first step in the jewelry manufacturing process is designing. Jewelry designers create sketches and computer-aided designs (CAD) to visualize the finished product. This process involves selecting the type of metal, stones, and design elements to be used in the piece.

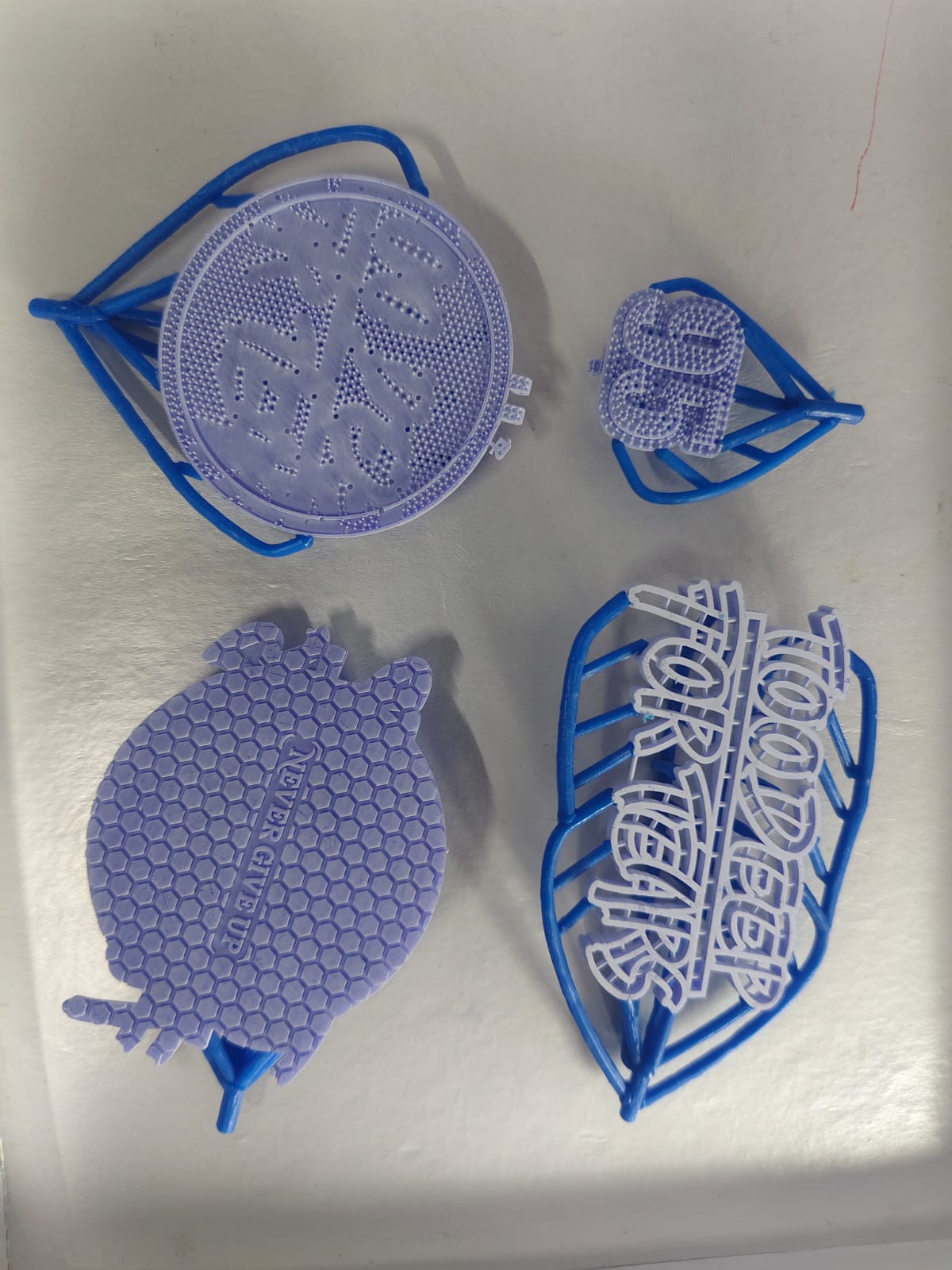

Step 2 : Wax Carving

Once the design is finalized, the next step is to create a wax model of the jewelry piece. The wax model is carved using a variety of tools and machines to ensure accurate measurements and shapes.

Step 3 : Casting

After the wax carving is completed, it is used to create a mold. The mold is filled with molten metal, which solidifies to create the final jewelry piece.

Step 4 : Cleaning

Step 5 : Setting

Step 6 : Polishing

After the stones are set, the jewelry piece is polished to give it a shiny finish. This process can involve using polishing machines, abrasive compounds, and hand-polishing techniques.

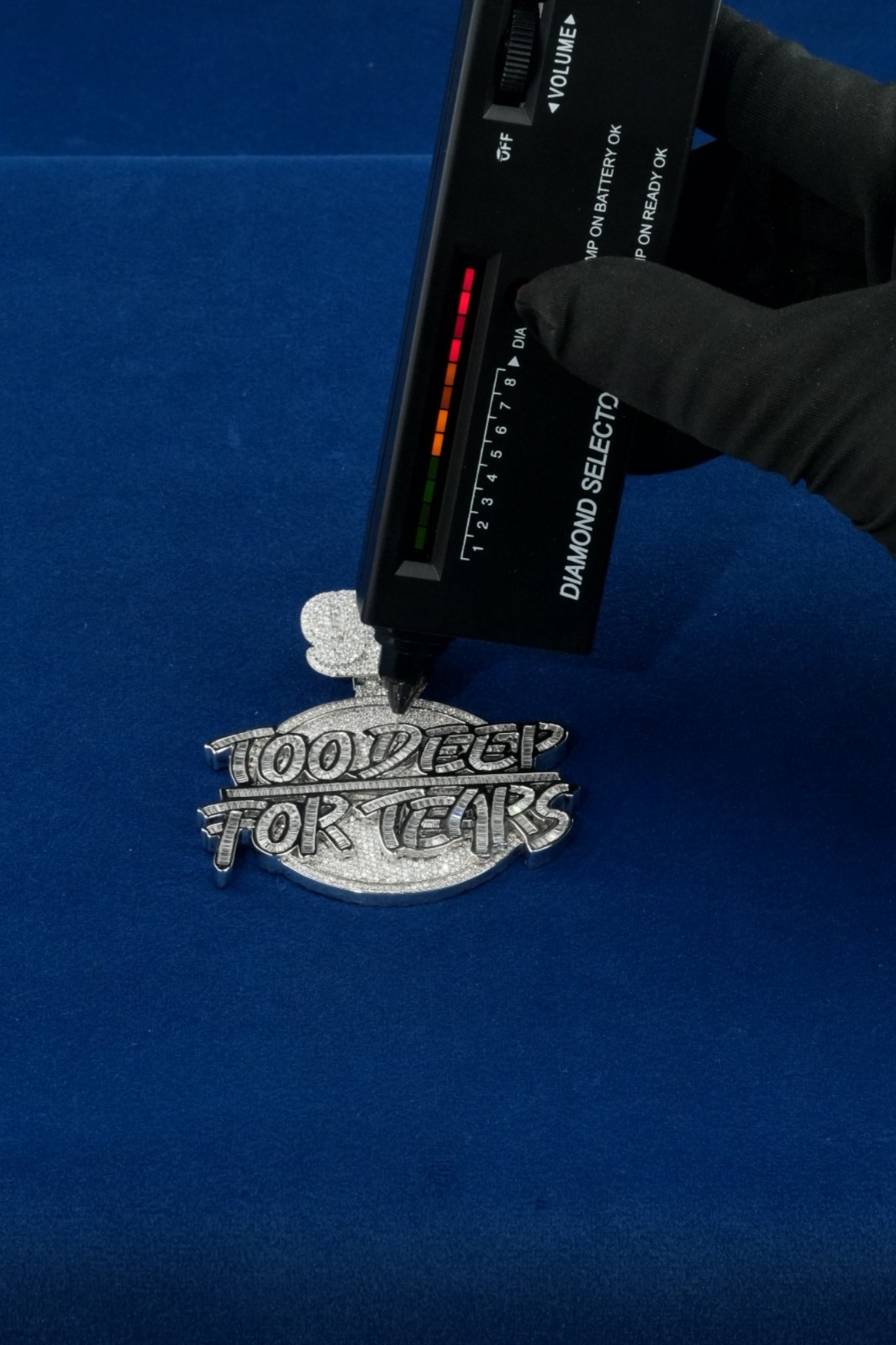

Step 7 : Quality Check

Once the jewelry piece is polished, it undergoes a thorough quality check to ensure that it meets the desired specifications and standards.

Step 8 : Final Touches

The final step is to add any finishing touches, such as engraving, plating, or additional stones.